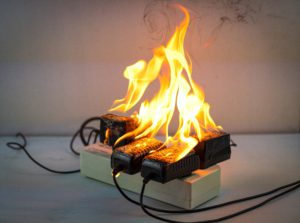

Explosions, and the subsequent fires, follow a similar pattern in the chemical industry so it begs the question, why doesn’t the lesson get learnt and safety management systems (SMS) get reviewed and improved for the experience learnt throughout the industry.

Managing risk is a crucial part of their business, they are the experts for defining and instituting safety controls based on identifying event failures and their consequences. Also, the event of the third party involvement of adverse weather conditions and the management of contractors.

Learning from the Past

For example, The Texaco explosion and fire (1994) when the release of 20 tonnes of flammable hydrocarbons formed a drifting cloud of vapour and droplets that found a source of ignition resulting in a massive explosion equivalent to at least four tonnes of high explosive causing severe damage and fires.

Weather conditions were traced to an earlier severe electrical storm that affected a number of the process units in the plant. The overall fail relates to the SMS and a number of coincidental failings that existed for some time and had come together in the explosion.

Similarly, on April 16th 2001 at ConocoPhillips Humberside refinery a major explosion and fire followed the release of 170 tonnes of highly flammable petroleum gas. The explosion was caused by failed pipe work. The investigation also revealed that there was a failing to inspect the pipe work at its site adequately. The Health and Safety Executive in its report emphasised that the main risks encountered were typical of the oil refineries in Britain.

And The Explosion at Lindsey Oil Refinery Limited on the 14th December had the same hallmarks. When the HSE investigation identified that the company had failed to adequately manage risks posed to workers carrying out maintenance work.

The incident involved contractors working on an out of service storage tank use, oxy-acetylene cutting equipment to cut floating roof brackets. The floating roof was at the bottom of the empty tank. The tank had been worked to a hydrocarbon free standard. The contractor standing on the top of the roof cut through the brackets, and a build-up of flammable oil vapour ignited.

Health & Safety Management Systems

Having contractors on site might be considered as a special case and as such must be considered as another risk potential to the business. The contracting company is likely to have a different safety culture, a particular agenda for completing the work, and the risk takers may not be familiar with the hazards that may arise in their contracted workplace.

This is just one of many risk that should be managed through a formal and documented health and safety management system.

ISO 45001 is the international standard that provides a framework for occupational health & safety management.

Assent’s safety consultants have experience in many industries, including the Chemical industry, and can help you build an effective safety management system for your organisation.

Contact us to find out how we can help you.